The old style Ninja 250s have a real ugly rear fender that sticks down and acts as a license plate holder and turn signal mounting point. I decided I had seen enough of it and wanted to clean the rear end of my bike up.

Not my bike but you can see how ugly that rear bit is.

My bike soon to be beautified.

The whole fender comes right off with a few bolts on the under side (the only thing holding it up there is the turn signal wires)

Taking appart the turn signals we found the metal bulb holders were flared into the plastic casing. This would need to be removed so we can move the turn signals elsewhere

unscrewing the brakelight in the back I noticed something pretty suspicious...

The hold on either side of the brake light seem pretty prefect for a bulb holder.

from the other side its pretty obvious that a turn signal could go there. What I think happened is the US required something that forced Kawasaki to make an additional fender and turn signals for their bikes sold in the US but in other markets they had the turn signals already integrated. This makes my job easy because I dont need to make a custom mounting for the turn signals!

taking out the old bulb holder

Fits perfectly!

Securing it in place with a little glue

Redoing and checking the wiring.

Bingo! We werent quite dont yet however because there needs to be a light to illuminated my license plate at night. I researched online how other people solved this and the most popular and simplest was to mount your plate under the brake light and remove a little pannel on the bottom so the light can shine down.

Super easy. Now all that was left was to trim up the old fender so the underside still protects my bike from rocks and mud and things.

trimming with a utility knife

done! The edges need some cleaning up maybe with a file but Ill do that later

Mike re installing the fender

All cleaned up!

It looks awesome. All thats left is a license plate holder. I have a temporary one on right now but Im going to CAD design a nice one and machine it out this week.

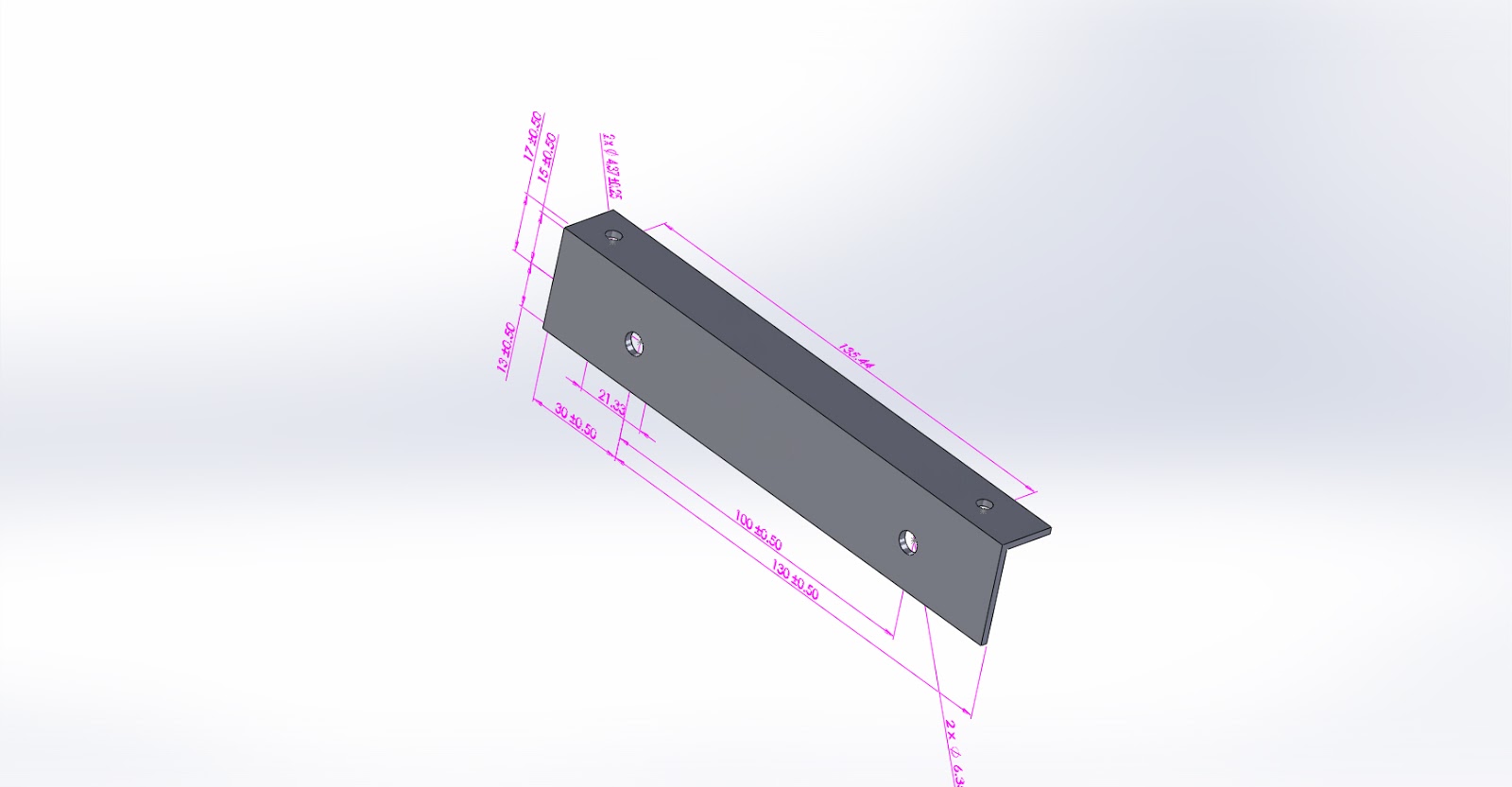

Simple plate bracket in Solid Works.